- Home

- level detectors

- NS/NT Electrode Level Detectors

NS/NT Electrode Level Detectors

Galvatek’s NS/NT electrode level detectors offer a reliable and precise solution for regulating and monitoring liquid levels in industrial tanks. Based on the principle of electrical conductivity, these passive sensors are ideal for demanding environments where process precision and safety are paramount. Given that these devices are entirely passive, the use of suitable electronic controllers (type ETS or ENR) is essential.

- Operating principle: Based on electrical conductivity (≥ 10 µS).

- Number of electrodes: 2 to 5 electrodes to detect up to 4 levels.

- Available materials:

- Stainless steel, titanium or PTFE Compound electrodes for optimum chemical resistance.

- Connection boxes in PP or PVDF (IP65).

- Compatibility: For use with process electronics (ETS100, ETS200, ETS410 and ENR300)

- Maximum temperature:

- Up to 100°C for PTFE Compound electrodes.

- Up to 90°C for titanium or stainless steel electrodes.

- Increased accuracy: Reliable detection of high, low and intermediate thresholds.

- Flexibility: electrodes can be cut to length on site (except for PTFE Compound electrodes).

- Chemical resistance: Robust materials for corrosive environments.

- Easy installation: various mounting options with compatible accessories.

- Reliability: Robust design minimizes interference and risk of failure.

- Chemical industry: level control in corrosive or aggressive solutions.

- Water treatment: Tank monitoring to prevent overflowing or running dry.

- Food industry: Precise detection in sensitive processes.

- Metal vessels: Ground electrode can be connected directly to the vessel.

- Protection standard: IP65 splash-proof enclosure (EN 60529).

- Anti-fouling design: Minimum distances between electrodes to avoid deposits.

- Process safety: prevention of overflows and protection of equipment (pumps, heaters).

Additional Resources

Find the installation manual for the NS/NT Electrode Level Detectors.

Options and Accessories

Universal key

Assembly Key SB for BC Head

For opening the LC terminal box and the cable gland.

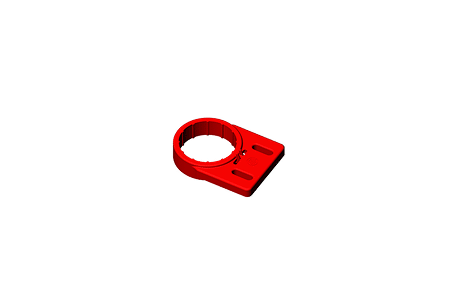

SL Mounting Key for LC Head

Red head material: PP, ref. LC - White head material: PVDF, ref. LC/L

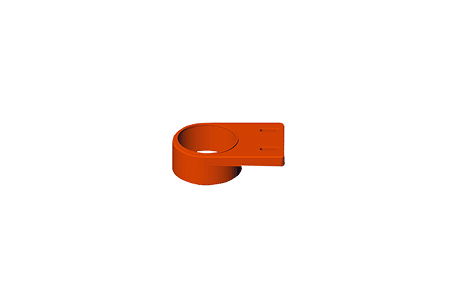

LC Terminal Box

Red head material: PP, ref. BC

White head material: PVDF, ref. BC/L

BC Terminal Box

For securing the immersion heater in tank cross-members, recommended for high-temperature liquids or those with high vapor release.

Bore diameter: 70 to 76 mm.

Material: EPDM

HM Mounting Sleeve for BC Head

Allows installation in confined spaces on tank crossbeams

bore diameter 63 mm

Material: EPDM

ML Mounting Sleeve for LC Head

Enables installation with a reduced footprint on tank crossbeams, bore diameter from 87 to 90 mm - Material: EPDM

EM Mounting Sleeve for BC Head

Fixed by screws on the tank rim, the terminal box easily slots in

For immersion heaters with LC head

Material: PP

HL Support for LC Head

Secured by screws on the tank rim, the terminal box easily slots in.

For immersion heaters with a maximum immersion tube length of 800 mm.

Material: PP

HB Support for BC Head

Discover our Other

level detectors

Calculez la puissance de votre installation en chauffage et refroidissement.

- Proposition technique 100 % adaptée

- Recommandations d’experts

- Confidentialité garantie

FAQ

Aucune FAQ disponible.